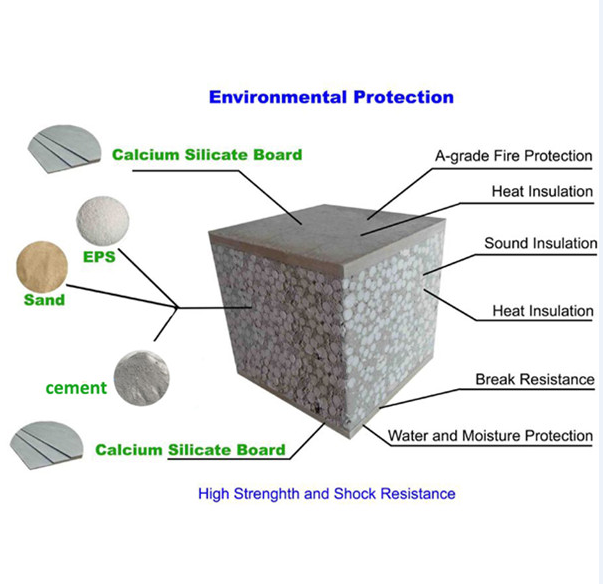

150mm thickness partition walls outdoor, lightweight eps cement sandwich wall panel, easy construction

Composition: Calcium silicate board + cemetn + EPS foam

Specification

Length (mm) | Width (mm) | Thickness (mm) | Density (kg/m2) | Application | Appearance |

2270 2440 | 610 | 50 | 38±5 | Commercial, residential and industrial construction | With calcium silicate board as face board, solid |

60 | 42±5 |

75 | 45±5 |

90 | 52±5 |

100 | 56±5 |

120 | 62±5 |

150 | 72±5 |

180 | 85±5 |

200 | 95±5 |

Technical Index

NO. | Item | National Standards | Testing Results |

60mm | 90mm | 120mm | 60mm | 90mm | 120mm |

1 | Anti-impact performance/times | ≥5 | ≥5 | ≥5 | ≥6 | ≥6 | ≥10 |

2 | Anti-bending damage load/times over deadweight | ≥1.5 | ≥1.5 | ≥1.5 | ≥3 | ≥3 | ≥3 |

3 | Anti-pressure strength /Mpa | ≥3.5 | ≥3.5 | ≥3.5 | ≥6 | ≥6 | ≥6 |

4 | Surface density kg/m2 | ≤70 | ≤90 | ≤110 | ≤45 | ≤54 | ≤66 |

5 | Single point hanging Strength /N | ≥1000 | ≥1000 | ≥1000 | ≥1000 | ≥1200 | ≥1300 |

6 | Fire proof limit /h | ≥1 | ≥1 | ≥1 | ≥3 | ≥3 | ≥4 |

7 | Sound insulation capacity in the air /Db | ≥30 | ≥35 | ≥40 | ≥35 | ≥40 | ≥45 |

8 | Soften coefficient | ≥0.80 | ≥0.80 | ≥0.80 | ≥1 | ≥1 | ≥1 |

9 | Moisture rate a/% | ≤12 | ≤10 | ≤10 | ≤10 | ≤9 | ≤7 |

10 | Heat transfer coefficient w/m2.k | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.0 | ≤0.6 | ≤0.5 |

11 | Drying shrinkage /mm/m | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.45 | ≤.0.5 | ≤0.5 |

12 | Inner radiation index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

13 | Outer radiation index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

14 | Radioactivity Limit | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

Installation

1. Setting the line and carrying the board into position;

2. Using a hand-hold electric saw to the sizes needed;

3. Sizing cement on tenon side of two boards, then spread polymer mortar on one tenon side casually;

4. Carrying the board prepared to be installed to the installation place, correcting the wall board by Special

tools, and making it close tightly, and let the polymer mortar squeeze out into full and then fixing it with a

wedge temporarily;

5. Planting bars in wall and pillar: drill a hole in the original pillar or wall, and fix the board by steel bars ;

6. Correcting and fixing: Using a guiding rule to check the vertical and leveling correction;

7.Planting bars in structure beam: drill a hole in structure beam and plant a reversed 7-shaped steel bar to fix with wall board;

8.Planting bars in floor: drill a hole in the floor and plant a 7-shaped steel bar to fix with wall board;

9. Planting bars between two boards, plant a steel bar in the angle of 45 degree to fix;

10. Installing electrical wires and switches: setting lines on the places needing to be set with concealed wire and switch box;

11. Grouting and filling starch: filling and sticking the corrected wall board with polymer mortar;

12. Sticking anti-cracking tape ;

After the polymer and wall are all shaped, sticking glass-cloth or anti-cracking tape, brushing coating.

Advantages

1.Energy Saving, Excellent Performance |

Heat Preservation | Major material for wall panel is anti freezing, heat preserving and environmental friendly. |

Heat Insulation | Adjust the indoor temperature at a constant range. |

Fire Proof | Both face sides with 4.5mm calcium-silicon fire proof boar, thus EPS Cement panel can be against a high temperature of 1000°C for 4 hours. |

Water Proof | Tests has proved that water containers can be made by EPS Cement panel without absorbing functions and no leakage at all. |

Sound Insulation | The inside of cement sandwich wall panel material(EPS polystyrene grain)has fine sound insulation and sound-absorbing functions. |

2.Easy Construction Process |

Easy to Install | Using our installation material(PU Foam and Cement Adhesive)is easy to build house. |

Shorter Time | For a 50sq. house, using EPS Cement sandwich wall panel, three people can finish it within ONE day, while using traditional block, it will take at least SEVEN days to finish. |

3.High Security performance |

High Intension | EPS Cement sandwich wall panel can be nailed directly or have expansion bolt to lift and hang heavies, it can be covered by ceramic tile, wall paper, wood panel, coating etc. |

Earthquake Resistance | The Seismic performance of EPS Cement sandwich wall panel is at a magnitude of 8.5. |

4.Space and Cost Saving |

Space Saving | EPS Cement sandwich wall panel with the thickness of 60mm~180mm,as a thin and solid new type construction material, it will save lot of construction space compared with the traditional block. |

Labor Cost Saving | As EPS Cement wall panel is easy and fast to construct. |

Foundation Cost Saving | As the weight of EPS Cement wall panel is only 1/12 of traditional block, it will save 2/3 cost on construction structure. |

Package and shipping

Application

Certification

FAQ

Q: What’s the basic information of your company?

A: Hubei Boyuejia Industrial Co.,Ltd is a specialized high-tech enterprise interprating the R&D,production, sale and installation of new energy saving lightweight wall materialand the manufacturer of relevant machinery. We have more than 150 professional personnal in our R&D, management, technology and operation fields at present, we can provide high technical support and after-sale services to our customer.

Q: Do you have any certificates or qualifications?

A: Yes. We have passed CE&ISO9001. Also, we have done fireproof test, the fireproof performance of our sandwich panel is 4 hours.

Q: Why should I choose Boyuejia panel?

A: We are a professional EPS cement sandwich panel manufacturer in China. We have professional work team, we can provide you top quality products and professional services. I believe Boyuejia panel is your best choice.

Q: Do you provide small samples?

A: Of course. We provide small sample to our customer for free, but as we get too many requirements for sample, we need our customers pay for the postage. Hope you could understand.

Give dear you best solution is our duty !